In the last year or so, we’ve been talking obsessively about all the new capabilities provided by the brand-new XMD-S. We’d love to say more, but at the request of our therapists, we’ve decided to cool it for a bit and talk about some things XMD has been doing well for years. There’s hundreds of tried, tested, and true features in XMD that have sadly been taken for granted. One such feature that’s saved many a mold-designer’s rear end, is Interference Checking.

Expert Mold Designer is about automation and making designers faster and better. Our Interference Checking tool is a good example of that philosophy. For years, mold designers equipped with XMD have relied on it to identify problem areas in the design, before they leave the design department.

How it Works

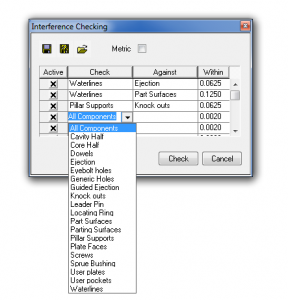

With XMD’s Interference Checking, you’re in the drivers seat. You simply tell XMD what features you’d like to have checked, give it the acceptable amount of tolerance your shop allows for, and you’re ready to go! Even better, you only have to do this once — any given configuration can be saved as a template, and simply loaded and executed the next time around.

Interference checks can be run as often as you’d like on almost anything you’d like, and take only a couple of seconds to complete, putting paranoid minds at ease.

The Report

Once you click the ‘Check’ button, XMD gets right to work checking all the specified conditions to their tolerance level. If you’ve done a good job, XMD will tell you there was “No interference found”. Give yourself a big pat on the back!

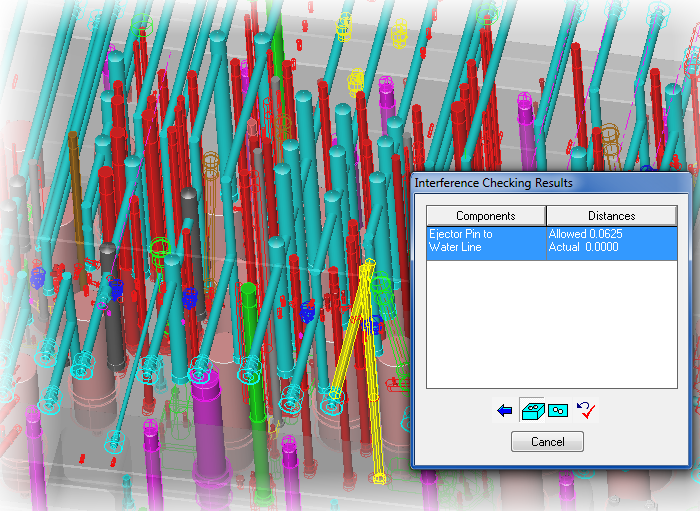

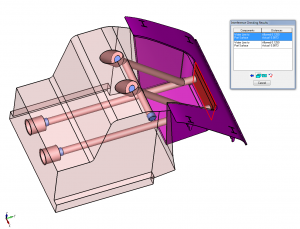

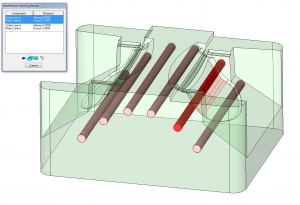

When problems do arise, and they will, XMD will list them in a well formatted report that lets you walk through the list of offending components. A sample execution is pictured to the left, showing two waterlines in a slide that are running right into the part. Not cool!

When each reported interference is clicked in the dialog, XMD automatically turns off all the levels except the ones showing you the problem area. It also highlights the particular entities related to that interference (notice the part surface that has been highlighted red in the picture). There’s also an option to see the report in a 2D drawing environment instead.

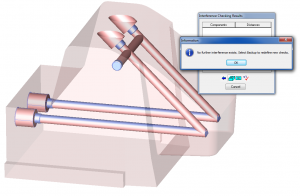

Back to the problem at hand. It would be nice to simply trim back those two waterlines while we’re looking at them and run the check again to verify the problem’s been fixed. Guess what! Interference Checking makes it easy to do just that.

The dialog will stay on the screen while you make your changes, and the button on the bottom right will re-execute the check. We’ve done just that using XMD’s Trim Waterline command, and the result is pictured on the right.

What’s New

OK, we couldn’t resist talking about XMD-S! What’s new in terms of Interference Checking? In the coming days, a new option called “plate faces” will be available to check interference against. This will check components against the critical faces of the plate solid(s) they are in. What are the critical faces you may ask? XMD can now analyze any given plate solid and identify what faces (if any) make up the part and parting line of the mold.

How will this be useful? This change is just one of many that will allow users to ditch the part and parting line geometry, and just work with the surfaced solid blocks. Designers will no longer have to update the surface geometry in two places, just on the plate solids. Stay tuned for a release announcement in the coming days.

Conclusion

Designing molds these days is complicated enough, and small mistakes have a bad tendency of costing thousands of dollars. The automation, intelligence, and quality control that XMD provides has a drastic effect on your bottom line. Interference checking is just one example of how XMD should be the #1 asset in a mold designer’s toolbox.