XMD-S 11.3 contains many new productivity improvements we’re excited about here at Cornerstone. This article will highlight the top three and explain how they will make you more efficient, and give you greatly improved control over the design process.

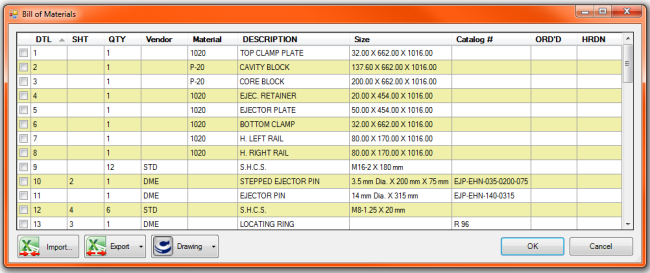

Bill of Materials

XMD’s Bill of Materials (BOM) utility has been a hallmark of our product for decades, and will continue to be for decades to come thanks to some major improvements we’ve made to it in XMD-S 11.3. Actually, improvements might not be the right word – we’ve completely re-built it from the ground up! All the old functionality has been maintained (and fixed in some cases) and we’ve also added some cool new features that will take things to a new level.

Users will now primarily interact with the BOM through a new dialog box which will be the go to spot for assigning and unassigning detail numbers, outputting the BOM to Excel, drawing it in the design, and making edits to the rows themselves.

One big new feature we’re excited about is that you can now bring in changes made to an exported materials list. This means that multiple users can now manage and share the design information, and any and all changes can be read back into the design instantly. We all know the dangers of working with out of date information. Thanks to the power of automation we’re working to make these sorts of problems a thing of the past.

Another new feature that will cut down on design time is that the BOM can now be used to drive the design. What do we mean? Let’s say you have a big job with 12 lifters and you need to change them to a different material. Instead of going to each lifter one by one and making the change, you can change the value in the BOM dialog box and the model is updated automatically.

Another big plus is that XMD-S is now much more active behind the scenes, keeping all the BOM information up to date automatically. The logic behind adding, removing, merging, and separating rows as components change has been thoroughly tested and will be sure to earn your trust.

As a final note, this is only the beginning. Thanks to these fundamental changes we’ve made, we’re now able to get started on some truly awesome purchasing improvements we have in store. Stay tuned!

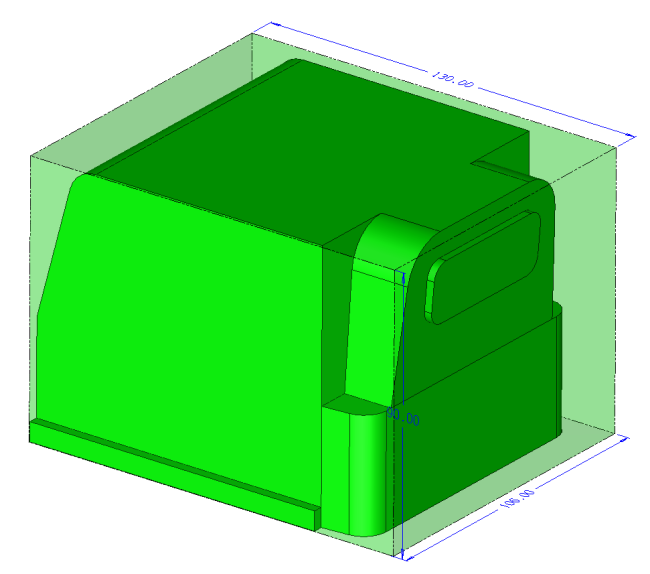

Stock Sizes for Plates and Custom Components

Up until now, stock sizes had to be hacked into the ordering information by either the designer or the purchasing department. Another foundational change we’ve made is to allow designers to specify stock sizes for all the plates and custom components in the design. This goes beyond just letting you key in some dimensions. We’ve taken advantage of KeyCreator’s powerful Dimension Driven Editing command to allow you to specify not only how much stock to add, but which sides of the plate to add it to.

What’s this mean for XMD-S? Depending on your configuration settings, stock sizes can be used for the BOM instead of the actual sizes. In the very near future, the Export Plate command will support the stock block as well as eyebolt charts.

Custom Component Libraries

It is now easier to work with custom component libraries. KeyCreator lets you edit properties on solid models, and save this to a file. XMD-S 11.3 will now read these properties and use them automatically. So you can create a library of your standard and custom components and bring these into XMD-S. The bill of materials will automatically use information, and you won’t need to re-enter it every time.

Coming Soon

Support for using part references for your custom solids. The advantages are many:

- Huge improvement on save time for solid plates.

- Remove duplication (identical plates will be able to refer to the same reference file).

- Foundational to creating custom component libraries for your shop.

- Bringing in newer models can be as simple as replacing a file.

We’d love to hear your feedback about these new features. Let us know what you think!